GHS Compliant: A Guide to Safety Standards and Regulations

In summary:

- GHS, or the Global Harmonized System of hazard classification, is a standard safety language adopted by the U.S., EU, and Canada

- Ensure you pay attention to your national rules when it comes to labels, SDS, and training

- Make SDS handling easier with version control and a single responsible owner through a comprehensive SDS solution

If you need to keep your location GHS compliant, then you will need to ensure that you focus on three primary pillars:

- Classification and labeling

- Safety data sheets (SDS)

- Role-appropriate training for employees

However, how do you handle the fact that the GHS is a United Nations framework rather than one produced in the United States?

Below, we discuss details such as:

- How the United States adopts GHS labeling standards through OSHA every two years

- What you need to update in terms of hazard communication and chemical safety standards

- Steps to meet GHS training requirements

So, read on to learn what changed in 2024 and 2025 and to discover what you might need to do to ensure that your workplace safety regulations are up-to-date.

What Does GHS Compliant Mean?

Being “GHS compliant” means that you follow the United Nations’ Globally Harmonized System for Classification and Labeling of Chemicals (GHS). United States employers do this by following OSHA’s Hazard Communication Standards, whereas other countries and regions have their own acronyms for a similar process, for example:

- The EU follows CLP

- Canada follows WHMIS

You can expect some differences between the countries, but all of them should stick to the requirements as laid out by the UN.

What Are GHS Guidelines?

The UN GHS defines:

- Hazard classes and definitions

- Rule templates

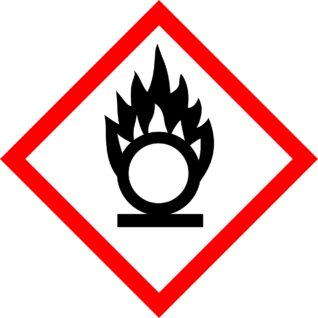

- Pictograms and iconography

These “guidelines” are building blocks, and local countries will add their own nuances without breaching the GHS’ rules themselves.

The most recent version of these rules can be found on the United Nations Economic Commission for Europe’s website, where all the rules are laid out in precise detail.

GHS Label Elements and SDS Essentials

All GHS documents, such as SDS, must include the same categories of details to ensure that people from different regions understand the contents of a container. For example, the rules detail what should be communicated in terms of:

- Unique product identifier

- Supplier details

- Hazard statements

- Precautionary statements

- Picographs and labels

If you must include more detail than this, ensure that you never obscure any of the information required by the rules.

US OSHA HazCom Alignment

Although the GHS is not up to revision 11, the most recent OSHA Hazard Communications Standards, issued in 2024, align broadly with GHS Revision 7. They have specific allowances for small containers and SDS technical requirements that were not handled by previous documents.

However, there are no additional updates at present. Should they change again, you can expect a period in which you have time to make changes to your processes and training to maintain parity.

EU, CLP, and Global Adoption

Recently, the EU introduced several new classes of substances, including:

- Endocrine disruptors (ED HH and ED ENV)

- Persistent bioaccumulative and toxic substances (PBT)

- Very persistent and very bioaccumulative substances (vPvB)

- Persistent mobile and toxic substances (PMT)

As such, if you trade with the EU market, or your products might reach there, you will need to update your labeling and training processes. If you need to comply with CLP for any reason, you must meet the following timelines:

- May 1, 2026: New products must be classified taking into account these new hazard classes

- May 1, 2028: Products already on the market must be classified following the new requirements

However, before these times, you may still voluntarily apply the hazard classes to substances.

Frequently Asked Questions (FAQs)

Who Requires GHS Labels and What Elements Must Appear?

By law, all businesses that supply or use chemicals must label their shipped containers and workplace containers with appropriate information in English, at a minimum. However, you should also add other languages as befits your workplace.

Details you need include things like:

- Pictograms

- Signal words

- Hazard and precaution statements

- Product identifiers

- Supplier data

If space limits exist, such as on smaller workplace containers, you may use alternative methods to label the chemicals. For example, a sign in the storage area or key training in operating procedures. KHA provides software to make this process easier and enhance your internal HazCom management.

Is GHS the Same as WHMIS and CLP?

GHS is a standardized model. Conversely, WHMIS and CLP are national and regional versions, much like the United States’ own Hazard Communication Standards.

As such, WHMIS, the Canadian standards, and CLP, the EU standards, attempt to adopt GHS in their own way.

Each local region is permitted to add its own additional classes or guidance beyond what GHS specifies, but the global harmonization standards serve as a baseline for all to ensure HazCom works internationally.

How Often Is GHS Updated and Where Can You Track Changes?

The UN’s GHS has typically been updated once every two years. However, this is only a precedent and is not set in stone.

As such, track UN GHS releases to be aware of what rules are likely to appear in the near future, then follow OSHA’s information in the United States to understand the adoption deadlines for each new rule.

What Training Is Needed for GHS and Who Must Take It?

You will need to train all workers who handle GHS-relevant materials on the label elements and pictograms that may appear on any containers. However, you should already be covering this in OSHA HazCom training.

Ensure You Know How to Handle the Requirements

Base your efforts on your local regulations to ensure you remain GHS compliant. For U.S. employers and suppliers, this means adhering to OSHA guidelines. Then, ensure you have an update procedure in place for labels, SDS, and training to bring everything up to speed.

If you need to simplify this process, KHA’s Online-SDS systems can help in many ways with OSHA compliance and SDS management. With multi-site support, offline access, and a mobile solution to keep everyone updated on the latest data at all times, we can help you avoid the gaze of OSHA and the potential of fines.

Contact KHA to learn more about what we can offer you and discover the seamless process of updating to our cloud-based SDS system today.