Solving the Mysteries of HazCom Labeling

If you’re reading this article then chances are you work with potentially hazardous chemical materials in your workplace. Because you work with potentially hazardous chemicals you already know that OSHA’s HazCom Standard is crucial for compliance and worker safety.

However, we see HazCom violations are at the top of OSHA’s “Top Ten Most Frequently Cited Standards” list online, year after year. Going back to 2002, you’ll find HazCom violations have not dropped below the number three spot during that time. Why is HazCom such a citation magnet for companies?

It’s because HazCom compliance is determined by more than the presence of chemicals. The quantities, frequency of use and if or where the chemicals may be shipped all help determine which standards apply. An additional factor is the adoption of and transition to the Globally Harmonized System of Classification and Labeling of Chemicals (GHS). With that said, we’ll take a look at some of the most frequently asked questions regarding HazCom labeling and attempt to clear up any confusion about how to stay compliant.

How do you know which chemicals need HazCom labels?

OSHA standard 1900.1200 (Hazard Communication, Toxic and Hazardous Substances) defines hazardous chemicals as “any chemical which is classified as a physical hazard or a health hazard, a simple asphyxiant, combustible dust, pyrophoric gas, or hazard not otherwise classified.”

Although it is not a comprehensive list of all potentially hazardous chemicals, OSHA standard 1910.119, Appendix A is a helpful list of highly hazardous chemicals which would require HazCom labeling. This list is very helpful as it also lists the threshold quantities.

Keep in mind, any new hazardous chemical that arrives at your facility should already come with labels that are fully GHS-compliant. However, if you are transferring those chemicals to other (secondary) containers, then you will need to create additional GHS-compliant labels for the secondary containers.

Secondary container labeling can be tricky to navigate due to certain exclusions included in the HazCom standard. The simplest way to be certain you’re in compliance is to always label secondary chemical containers with full GHS labels. Below are some use case scenarios for your consideration.

Portable containers – Containers intended for immediate use by one employee are excluded from HazCom labeling. For instance, each day an employee pours a cleaning solution into a bucket and cleans the facility with the solution. When finished the employee disposes of the solution. The container used for the cleaning solution does not require a HazCom label while the employee is using the cleaning solution.

The requirements change when the employee uses the same cleaning solution but wants to leave it behind for another employee to use; in this case a HazCom label would be required. In addition, if the employee wished to store the mixture for future use, the secondary container for storing the cleaning solution would require a HazCom label.

Consumer Use – Consumer chemicals, given that the user is following the recommended use instructions of the manufacturer, do not require HazCom labeling. A good example of this is a basic household cleaning spray you could buy at the grocery store. Keeping it on hand in your break room for employees to clean up after themselves would not require HazCom labeling.

Substances covered under other regulations – Substances that are regulated by other government agencies or statutes do not fall under the HazCom labeling requirements. Some examples include: hazardous waste (RCRA), pesticides, cosmetics and drugs for personal consumption (FDA), food (USDA), consumer products (CPSC), and chemicals regulated under the Toxic Substances Control Act, which is administered by the EPA.

Which label type should be used? HMIS & NFPA vs. GHS labels

GHS labels were adopted by OSHA as part of the updated HCS in 2012, so this format is still fairly new to some people. With that said, it makes sense that the question still arises as to whether or not to continue to use the previous voluntary workplace labeling systems or move entirely to GHS labels.

Previous to 2012, labeling systems such as the Hazardous Materials Identification System (HMIS) and the National Fire Protection Association (NFPA) were the most pervasive voluntary workplace HazCom labeling systems in use. The hesitation to fully switch over to GHS labels may be due, in part, to the time and money required to replace old labels.

There’s no doubt that resources play a role in HazCom labeling, there is also a case to be made for “sticking with what you know”. The people who have been trained on HMIS and NFPA are more comfortable with those systems and may find GHS HazCom labels confusing. The pressing question for many employers is: “Can we still use HMIS and NFPA labels?”.

The official answer from OSHA, found on osha.gov states, “Yes, OSHA will continue to allow NFPA and/or HMIS rating systems on labels and SDSs as supplemental information. However, the rules for labeling and placement on the SDSs still apply.”

The current regulations allow for the use of existing labeling systems such as HMIS and NFPA as long as they are consistent with the current requirements of the HCS. Also, supplemental labels can only be used for chemicals on-site within the facility and employees must understand the specific physical and health hazards.

While you may be allowed to use HMIS and NFPA under the OSHA regulations, there are good reasons employers should consider the move to GHS labels exclusively.

First, any new shipment of chemicals that come into your facility will have GHS compliant labels. If HMIS/NFPA labels are used for secondary containers in your workplace, then employees need to be trained on both systems. So it makes more sense to move to GHS compliant HazCom labels in order to streamline employee training.

Secondly, the required information on hazardous chemical labels, as outlined in OSHA regulation 1910.1200(f)(6)(ii), include physical and health hazards. These elements are not typically found on HMIS or NFPA labels which can cause confusion on the part of employees. Employers must prove that employees understand the hazards as well as they would have with a GHS label if an employer continues to use HMIS or NFPA labels in the workplace.

Finally, the numbering system for HMIS and NFPA are the opposite of GHS. One is the monster serious hazard rating for GHS and the least serious for both HMIS and NFPA. While the numbers are not displayed on GHS labels, this still has the potential to cause confusion.

GHS Labeling: Required Information

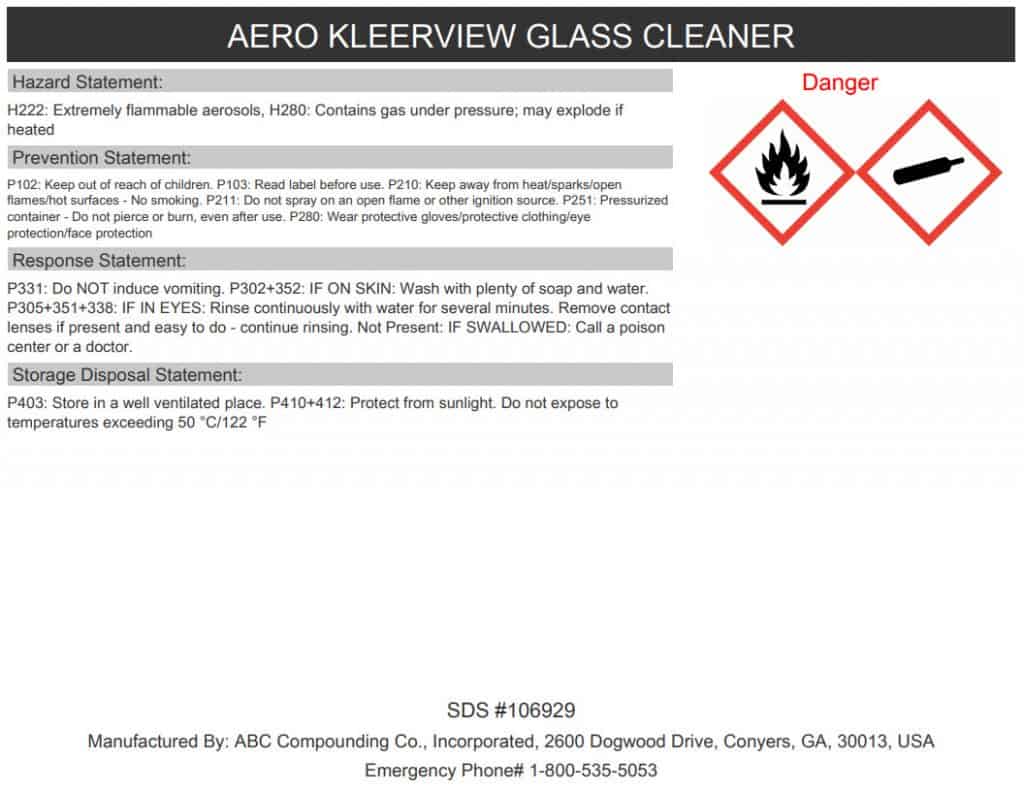

There are six required elements for a fully compliant GHS label including:

- Product Identifier

- Signal Word

- Pictograms

- Hazard Statements

- Precautionary Statements

- Supplier Information

Below is an example of a GHS-compliant label which includes each of the six required elements listed above.

All of the information listed above is available on the safety data sheet (SDS) provided by the supplier with the chemicals that are purchased. If the SDS is missing or is in the old MSDS format, the chemical manufacturer should be contacted to request an updated SDS.

Having an updated SDS is critical for accurate, compliant HazCom labeling. SDS are divided into 16 sections, Section 2 Hazard(s) Identification includes all the information needed to create GHS-compliant HazCom labels. There are also tools, such as KHA Online-SDS™ management, that streamline GHS label creation with time-saving features that auto-fill GHS information when creating labels.

How to battle against Label Wear & Tear

While there are no requirements as to which label stock you should be using for on-site chemical container labels, standard paper labels designed for office applications can’t stand up to the wear and tear of industrial spaces. HazCom labeling doesn’t do anyone any good if the labels are missing or illegible, which can be a struggle in demanding, heavy-duty work environments.

Durable label stock made of materials like polyester with aggressive adhesive helps decrease the chances of being non-compliant during an audit. Industrial labels for HazCom should stick to a wide variety of materials such as plastic, glass and metal, and also have some resistance to chemicals.

The use of marine-grade labels engineered for GHS labels used in shipping can further increase the longevity of your HazCom labels. Labels that are compliant with GHS shipping standards are waterproof, resist chemicals, abrasion, UV fading, tearing and have been tested to stay adhered in seawater for at least 90 days. Look for labels that say BS5609-compliant and have been tested to meet such requirements.

Conclusion

Label requirements have changed throughout the years, but it appears that GHS-compliant labels are here to stay for the foreseeable future. While you may still be allowed to use older labeling systems such as HMIS and NFPA, adopting a GHS-compliant labeling system will streamline your operations and increase employee safety. It’s also a good idea to seek out a SDS management solution that will populate labels for you.